Branson 2019 B950R Ultrasonic Vapor Degreaser with Automated Robotic Basket in Pristine Condition only 3 years old!

Branson 2019 B950R Ultrasonic Vapor Degreaser with Automated Robotic Basket in Pristine Condition only 3 years old!

$34,995 (USD)

Location:Central Falls, RI

Description

This is a 2019 B950R Branson Ultrasonic Vapor Degreaser with Automated Robotic Basket in Pristine Condition!

Only 3 years old! ...call us for a demonstration!

B950R VAPOR DEGREASER

- Serial# 08-6275-19

- Year 2019

- 208 volts / 3 Phase

- Freq 40 Khz

Branson Model B950R ultrasonic vapor degreaser, to be furnished in accordance with the

following specifications:

• Boil sump and ultrasonic sump to be constructed of heli-arc welded type 304

stainless steel for corrosion resistance

• Internal working dimensions of:

Ultrasonic sump: 12" L x 16" W x 12" deep

Boil sump: 12" L x 16" W x 12" deep

Vapor zone: 32.75” L x 19.25” W x 12” deep

Freeboard Zone: 36” L x 22.5” W x 20” deep

• Solvent Capacity:

Boil Sump Working Capacity: 13.8 gallons

U/S Sump Working Capacity: 10 gallons

Water Separator Capacity: 1.5 gallons

Total Solvent Capacity: 26 gallons

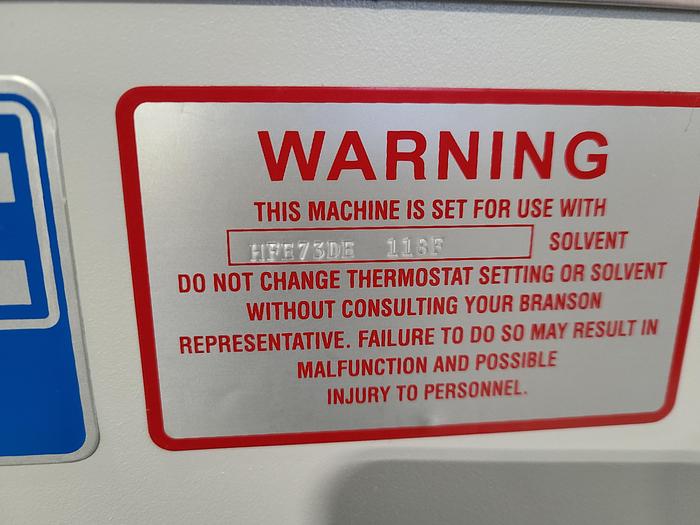

SOLVENT TYPE: HFE73DE / BOILING POINT: 118F

Solvent Cleaner for this unit...

AeroTron-100 Non-Flammable Precision Cleaning and Vapor Degreasing Solvent

Boil Set Point 113-116F

Ultrasonic Sump Set Point 90F

• Vapor/Air Interface 4.4 square feet.

• Unit to be skirted and painted with gray, solvent-resistant paint.

• Insulation will be provided on vapor zone, and freeboard zone area

The S8500 full feature generator model S8540-12 provides precise control of critical

ultrasonic cleaning parameters. All models come equipped with the following features:

• Branson’s new Auto Tune feature adjusts to the specific tank load while

constantly maintaining optimum operating frequency around your application

under a variety of changing process parameters such as:

Bath temperature

Liquid level depth

Load variations (size and weight)

Chemical viscosity

• Auto Tune feature dynamically adjusts to the optimum operating frequency as

these parameters change insuring precise bath control with consistent and

repeatable cleaning performance

• Line/Load Regulation: Compensates for liquid level, temperature, line voltage,

and load variation to less then 3% change

• Power Modulation: Provides increased peak power within bath for aggressive

cleaning and for difficult to cavitate cleaning chemistries. Can also be used to

degas liquids

• Sweep Frequency: Selectable sweep rate and band width to minimize standing

waves and improve ultrasonic distribution

• Variable Power Control: Cavitational power adjusts from 10 to 100% for

matching cleaning power precisely to the application

• Average output power: 500 watts

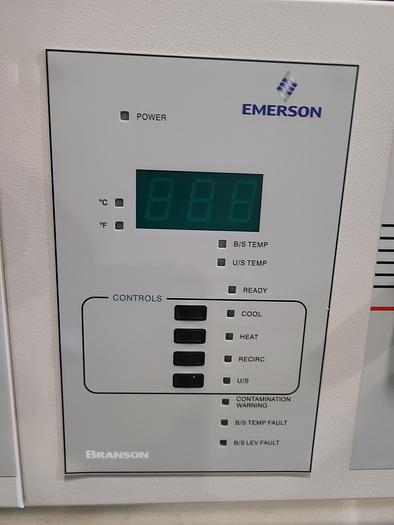

• Comprehensive User Friendly Control Panel: Status indicators provide visual

confirmation of functional parameters

• CSA Certified, complies to FCC part 18 (CE Available)

• Operating Frequency: 40 kHz

• Voltage: 208-230, Single Phase, 60Hz, 4 amps

• Line cord configuration: NEMA L6-20P

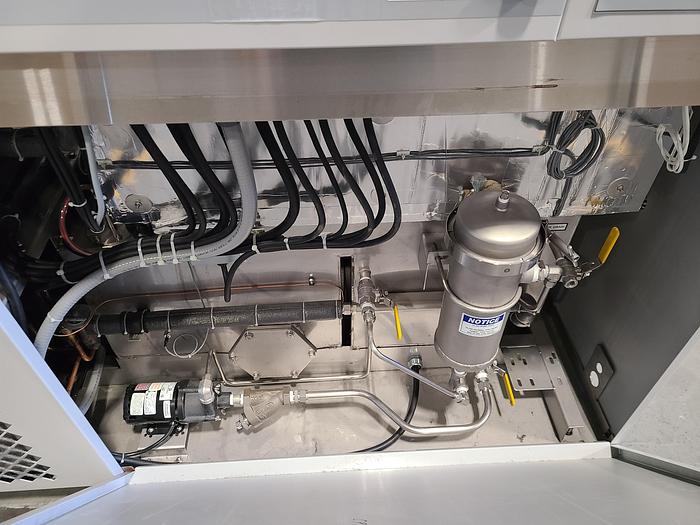

• Unit to be furnished with a recirculating pump and bag filter system, for the ultrasonic

sump for efficient particulate removal. Ryton pump to be sealless, magnetic drive.

Recirculating rate to be 2 GPM

• 24 Volt controls, for operator safety

• Constant digital display of boil sump or ultrasonic sump temperature

• Standard safety features:

Ready Light

Coolant Temperature Sensor

Boil Sump Temperature Fault

Boil Sump Level Fault Indicator

Early Warning Contamination Indicator **

**Other fault conditions will appear in temperature display

– IDS Page 5 of 5

• All solvent wetted materials to be stainless steel, Ryton (pump), Teflon (seals), and

nylon (filter element)

• Boil sump heat: 4,000 watts stainless steel low watt density immersion heat,

contained in offset boil sump with low liquid level safety control

• Ultrasonic sump heat: 800 watts

• Clean out door on boil sump for ease of maintenance

• Average Distillation rate: 14 GPH *

*(Based on use with HCFC, HFE, HFC solvents.)

• Power requirements: 230 VAC, 50-60 Hz., 3 phase, 37 amps (208 Available)

• 100% Freeboard area meets NESHAP regulations. Unit will be equipped with two (2)

cooling zones for emission control

Primary coil at 20 to 45 degrees F

Freeboard (secondary coil at 0 to -20 degrees F)

• Primary and secondary coils will share a common internal water separator from

separate troughs

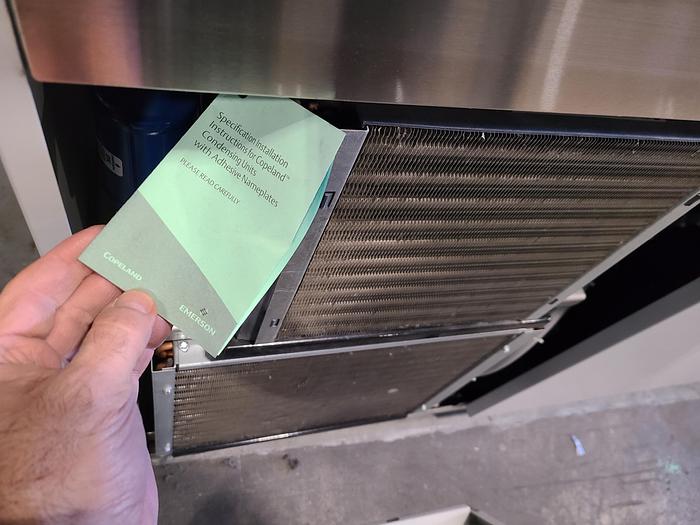

• Refrigeration for primary coils provided by a 1-1/2 HP direct-expansion condensing

unit.

Refrigerant: R134A.

• Refrigeration for secondary coils provided by a ½ HP direct-expansion condensing

unit.

Refrigerant: R404A.

• Drain valves conveniently located behind removable panel for easy access

• Overall dimensions: 64.75" L x 32.5" W x 48.75" High

• Approximate shipping weight: 750 lbs.

• Desiccant kit optional and required for certain solvents.

The B950R will be supplied with an internal Dual Axis Lift Mechanism as follows:

• For use above and into the boil sump and ultrasonic sump

• The operator will load and unload the parts onto and off of the lift mechanism above

the degreaser

• The lift mechanism will process the parts (vertical and horizontal movement) as

follows: vapor zone over the boil sump, immersion into the boil sump (only if

required), vapor rinse, freeboard dry

• Variable process dwell times via PLC Direct PLC

• Pneumatic air cylinder with limit switches, for vertical motion

• Rod-less air cylinder with limit switches for horizontal motion

• Dual start push buttons

• Opens and closes power cover (if equipped)

• Maximum weight capacity: 50 Lbs

• The speed of the lift is factory set to comply with NESHAP regulation (field

adjustment is not recommended)

• The overall height of the B950R will increase to approximately 95.5” with the lift

in its uppermost position. (The overall width will increase by approximately 5.5").

If the B-950-R will have a dual axis lift mechanism installed, for safety reasons the

automatic mode on the degreaser will be semi-automatic. This means that both START

switches must be pressed at the same time to initiate any motion of the lift. This prevents

the lift from starting into motion while the operator has a hand or arm inside the

degreaser

Power Cover

• Pneumatically activated power sliding cover

• One piece, full open capability for non-automated operation*

• Helps to reduce processing emission losses

• Customer supplied air requirements: 60 to 120 PSIG, .5 SCFM

Note: Power cover will increase the overall height of the B950R to 52"

Note: All dimensions shown above are in order left to right, front to back, high/deep.

Note: Approximate Room Heat Load: 40,000 BTU/hr

WSPT # LCCAF-000000-030522-D

Picture# 030222

Bid with Confidence on this item, check our feedback!!!

* All information deemed accurate but may vary from model to model.

Contact Larry for any questions you may have...

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

___________________________________________________

Equipment Financing Available, please contact us!

Fast Application, it’s all filled in for you...

Online leasing applications (get LOW monthly payments)

* Please Note: Not all machines may qualify for Leasing.

Payments: We accept all Major Credit Cards, Bank Wires, Company and Personal Checks.

SHIPPING: Contact us for great rates on shipping...

We always get better rates...

Please email us for a rigging and shipping quote; just include the zip code when inquiring and if you have a loading dock or ground level with forklift. Thank you!

Contact us at Four Zero One - Nine Six Five - Five Five Five Seven

We also ship worldwide.

CONDITIONS: All quotations are for immediate acceptance. They are subject to withdrawal, change and prior sale without notice. Shipping dates are only approximate and contingent upon delays beyond our control. All orders received are binding only when they have been accepted and acknowledged by us in writing. Provisions in customer’s purchase orders contrary to these conditions shall not be binding upon us unless accepted in writing. Unless otherwise specified, prices quoted are F.O.B. shipping point, exclusive of State, County and Federal taxes which must be added where applicable. Insurance on shipment must be requested by email, there will be an additional charge for shipping insurance. Shipping destination must be available to receive the shipment… any costs incurred on delays due to the buyers’ destination being unable to receive the shipment and/or additional services required, will be the responsibility of the buyer. Care is taken to give reliable specifications, but these are not guaranteed. We reserve the right to correct typographical errors. All used equipment is sold "as is".

INDEMNIFICATION: Used Machines may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It is the user's responsibility that the said machines be so equipped and safeguarded to meet OSHA and any other requirements before placing such machinery into operation. User agrees to indemnify and hold Seller harmless of and from any and all claims or liabilities from accidents involving these machines caused by failure of user, his employees, or agent to follow instructions, warnings, or recommendations furnished by manufacturer, or Seller, or by failure of user to comply with Federal, State and Local laws applicable to such equipment including the Occupational Safety and Health Act of 1970. User shall notify Seller promptly after occurrence of any accident involving these machines, and shall cooperate fully with Seller. or Seller's agent in investigating and determining the cause of said accident.

Specifications

| Manufacturer | Branson |

| Model | B950R |

| Year | 2019 |

| Condition | Used |

| Serial Number | 08-6275-19 |

| Stock Number | 030522D |