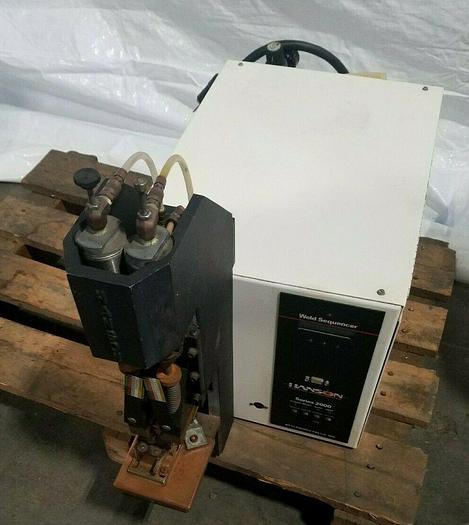

Hanson Weld Sequencer Series 2000 RESISTANCE WELDING & SOLDERING MACHINE NOT WORKING PARTS ONLY

Hanson Weld Sequencer Series 2000 RESISTANCE WELDING & SOLDERING MACHINE NOT WORKING PARTS ONLY

$495 (USD)

Location:Providence, RI

Description

Hanson Weld Sequencer Series 2000 RESISTANCE WELDING & SOLDERING MACHINE NOT WORKING PARTS ONLY

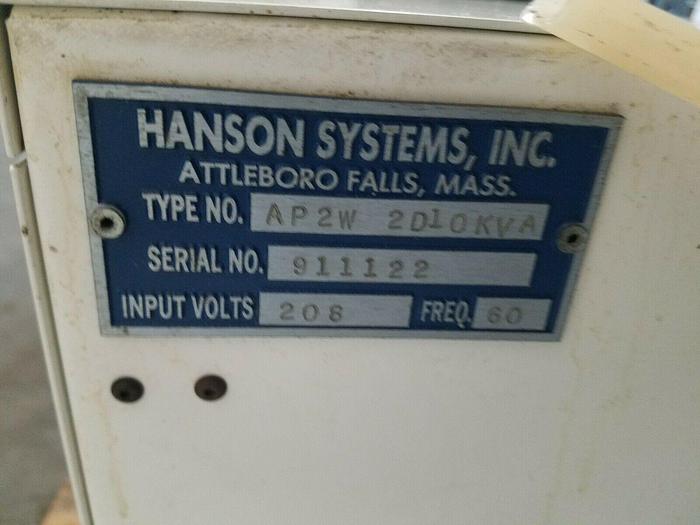

Type #AP2W-2D10KVA Serial #911122 Series 2000 Input Volts: 208 Freq. 60 RESISTANCE WELDING & SOLDERING MACHINE... Series 2000 - 1 to 20 KVA In the 1-20 KVA range, Hanson offers a fully integrated benchtop welding and soldering machine system. That is our model AP-2W resistance welding and soldering machine. It is offered with a wide range of options that permits the customer to virtually custom design each machine to meet his particular requirements. Features/Benefits Series 2000 Control Microprocessor-based controller stores programmable, preselected weld schedules. Schedules are programmed and recalled through a hand-held pendent that prevents unauthorized changes. Unique approaches to voltage compensation and phase shift heat control eliminate variables that cause inconsistent welding performance. No other controller can match the degree of precision and consistency provided by the Series 2000. Head Assembly Designed for Durability and Consistent Performance. Low-inertia linear precision cross roller slide head assembly assures continued smooth operation and repeatable performance. Rugged construction for long, trouble-free service. Head Force System Guarantees Precision Weld Performance. The head force system is in direct alignment with electrodes. This enables follow-up response not available in cantilever-type heads and assures precision weld performance. Special Head Firing Switch Insures Repeatability and Reliability of Welds. A reliable feature on all Hanson welders. It allows the welding control to be fired only when the predetermined force range has been reached by measuring the displacement of the head force system. Transformer Design Minimize Possibility of Saturation. Multi-tapped stacked core, epoxy-impregnated design, using high-grade silicon steel. Built-In Versatility to Handle a Variety of Jobs. Force system, stroke, electrode opening and squeeze and hold times are all fully adjustable to accommodate a wide variety of parts sizes, materials and fixturing. Modular Construction Permits Equipment Modification in the Field. If requirements change, a welder can be modified by changing transformer and/or force control springs and indicators. Convenient No Heat/No Weld Switches for Safer, Easier Set-Up. Minimizes chance of operator injury, set-up times are reduced. Applications The basic versatility of the AP-2W welder and the many options and accessories available make it suitable for welding a wide range of small to medium-sized pads. These machines are widely used in electrical/electronics, automotive, appliance, aerospace, jewelry and metal-working industries in metaljoining applications where precision is essential. Specifications MODELS Model AP-2W single ram resistance welding and soldering machine. Model AP-2W-2D dual ram resistance welding and soldering machine. Welding/Soldering Head OPERATION Standard Air Operated. Low-Inertia precision cross roller slide Head Assembly. Complete with all pneumatic circuitry and footswitch actuator. Two operating modes: semi-automatic and automatic HEAD ASSEMBLY Standard Air Operated Single Ram Head Options Standard Air Operated Single Ram Head Air Operated Dual Ram Head with Twin Cylinders (one independent cylinder for each ram.) FORCE SYSTEM, FULLY ADJUSTABLE Six Standard spring sizes provide: 0-12 lbs 0-24 lbs 0-48 lbs 0-72 lbs 0-96 lbs WATER-COOLED ELECTRODE HOLDERS Standard 3/8" diameter 1/4" diameter Options Other sizes available, either straight or with morse taper at extra charge. Consult Hanson Welding Machines before ordering. FULLY ADJUSTABLE LOWER TOOL HOLDER Provides up to 4" electrode opening. STROKE ADJUSTMENT CONTROL Allows control over head stroke from, 1/4" to 1" of electrode travel. Die set electrode tooling can be provided on special order. Transformer Multi-tapped stacked core design using high grade silicon iron. RATINGS Specify One 1 KVA 2.5 KVA 5 KVA 10 KVA 15 KVA 20 KVA PRIMARY VOLTAGE Standard Voltages Available (AC Single Phase). Specify One. 110 volts (1 KVA models only). 208 volts. 240 volts. 480 volts. Options Special voltages available on request. FREQUENCY Standard Frequencies Available. Specify One. 50 hz. 60 hz. SECONDARY VOLTAGE 8.0 volts standard. Custom voltages available on request. Note: This voltage is the maximum value at the highest tap setting. TAP SELECTION Standard 12 Tap and series parallel primary windings with center tapped secondary. COOLING Standard Air Cooled Secondary Option Water Cooled Secondary Welding and Soldering Controls Series 2000 Microprocessor-based, Programmable Weld Controller: Stores pre-selected weld schedules. Automatically controls Percent Heat, Squeeze Time, Weld Time, Hold Time. Heat Time Range: 1/2 cycle to 100 cycles Schedules are programmed and recalled through a hand-held programming terminal that prevents unauthorized weld schedule changes. Automatic line voltage compensation every 1/2 cycle of weld, starting with first 1/2 cycle. Unique phase shift control provides true under-the-curve adjustment for consistent welds. Battery back-up to protect memory RS232 port provides input/output interface Polarity selection switch and half-cycle control. Manual and automatic mode selector. Used to establish set-up parameters. Allows single stepping each sequence function when in manual mode. Heat/no heat selector switch. Used for set-up and dry cycling. Back-to-back SCR firing circuits. Head Firing Switch. Allows welding control to be fired only when the predetermined force range has been sensed through the displacement of the head force system. Two-Stage Foot Switch Initiation. In manual or semi-automatic mode. Up slope/down slope option. For applications requiring gentle heat-up prior to full weld energy or controlled cool down. Preheat/post-heat (quench and temper) option. Selectable in straight line steps. Preheat useful for brazing flux activation; post heat as an annealing function. Electronic cycle counter. Options Weld Monitor Weld monitors have been available for many years. Unfortunately, most of these devices are either current, or milli-volt second monitors, neither of which satisfy the basic requirement. To properly evaluate a weld, we must establish a correlation with what is happening electronically, and the mechanical test results. To do this we must have weld monitoring instrumentation capable of providing the necessary information. To properly monitor a weld, the equipment must measure current and area under the curve on each half cycle in A.C. applications, and measure current and area under the curve for each weld in D.C. applications. Further, it must be capable of calculating the product of these and reporting in half cycle increments, for A.C. applications. This product is called the weld energy, which is expressed in wattseconds or joules. Finally, the weld monitor must be capable of accepting both upper and lower control limits with alarms to alert, or shut down the process. Only Hanson Welding Machines, Inc. offers such a device. The optional weld monitor is an integral part of the Series 2000 Weld Control, and measures energy in real time, unlike remote add on monitors. It is fully programmable for upper and lower process control limits. The weld monitor audits every half cycle of weld, capturing the readings for current(in amperes) and milli-volt seconds (area under the curve). The product of these is expressed in joules of energy for each half cycle. The weld monitor protects against process shifts caused by dirty or worn electrodes, dirty or inconsistent product, equipment malfunctions, and countless other variables. The weld monitor stores the readings in memory for downloading to SPC packages for process capability analysis, or to printers for charting and evaluation. Other Options Two-hand anti-tie-down initiation circuit. Table mounted. Work Lights. Tooling and fixturing for your particular application. Weight and Size Weight, AP-2W: 150 lbs AP-2W-2D: 185 lbs Size, All Models: 13 1/4" wide x 22" deep x 22" high (overall). Palm Tree # LR-0000-091419LR-24 R040521 Bid with Confidence on this item, check our feedback!!! * All information deemed accurate but may vary from model to model. Contact Larry for any questions you may have... Contact us at Four Zero One - Nine Six Five - Five Five Five Seven or Contact us through ebay Google "Larry Razza" to see more information & videos of our equipment! L R Associates, Inc. / Palm Tree Specialties ebay store Rhode Island, USA ___________________________________________________ Equipment Financing Available, please contact us! Fast Application, it’s all filled in for you... Online leasing applications (get LOW monthly payments) * Please Note: Not all machines may qualify for Leasing. Payments: We accept all Major Credit Cards, Bank Wires, Company and Personal Checks. SHIPPING: Contact us for great rates on shipping... We always get better rates... Please email us for a rigging and shipping quote; just include the zip code when inquiring and if you have a loading dock or ground level with forklift. Thank you! Contact us at Four Zero One - Nine Six Five - Five Five Five Seven or Contact us through ebay Message We also ship worldwide. CONDITIONS: All quotations are for immediate acceptance. They are subject to withdrawal, change and prior sale without notice. Shipping dates are only approximate and contingent upon delays beyond our control. All orders received are binding only when they have been accepted and acknowledged by us in writing. Provisions in customer’s purchase orders contrary to these conditions shall not be binding upon us unless accepted in writing. Unless otherwise specified, prices quoted are F.O.B. shipping point, exclusive of State, County and Federal taxes which must be added where applicable. Insurance on shipment must be requested by email, there will be an additional charge for shipping insurance. Shipping destination must be available to receive the shipment… any costs incurred on delays due to the buyers’ destination being unable to receive the shipment and/or additional services required, will be the responsibility of the buyer. Care is taken to give reliable specifications, but these are not guaranteed. We reserve the right to correct typographical errors. All used equipment is sold "as is". INDEMNIFICATION: Used Machines may not incorporate approved activating mechanisms, operator safety devices or safety guards as required by OSHA or otherwise. It is the user's responsibility that the said machines be so equipped and safeguarded to meet OSHA and any other requirements before placing such machinery into operation. User agrees to indemnify and hold Seller harmless of and from any and all claims or liabilities from accidents involving these machines caused by failure of user, his employees, or agent to follow instructions, warnings, or recommendations furnished by manufacturer, or Seller, or by failure of user to comply with Federal, State and Local laws applicable to such equipment including the Occupational Safety and Health Act of 1970. User shall notify Seller promptly after occurrence of any accident involving these machines, and shall cooperate fully with Seller. or Seller's agent in investigating and determining the cause of said accident.

Specifications

| Manufacturer | Hanson |

| Condition | Used |

| Serial Number | 911122.0 |

| Country/region of manufacture | United States |